Bring Real-World Production Methods To Your Class And Take Control Of Resources And Cost

Written by Rebecca Walsh

Published on 4th November 2021

Last Updated: 29th July 2024

Written by Rebecca Walsh

Published on 4th November 2021

Last Updated: 29th July 2024

Naturally, with Design & technology, the need for various materials, equipment and resources can be high. Key National curriculum objectives focus on developing designing, making and cooking skills. However, it is not always essential to provide each pupil with their own resources; valuable lessons can be learned when forming part of a team, pair or assembly line.

When working together, pupils get the opportunity to develop their:

Below are three production methods that can be used to deliver primary Design & technology lessons with a difference and give you more control to manage the cost and number of resources required to complete each unit.

Limits resources to a set number of your choosing. Ensures there is still the opportunity for every child to complete various parts of the process in the assembly line.

Mass production is also known as flow or continuous production. Identical products are created continuously as part of an assembly line. Today, most are put together by highly technical automated machinery controlled by pre-written programs, sensors and robotics. Humans are only required to fulfil specialist roles such as machine maintenance or to start the manufacturing process by loading raw materials.

In this instance, we will step back in time to when robotics and automation were less frequent and allow the pupils to fulfil the role of managing a station along an assembly line. Each pupil (or pair/group) will carry out one specific job, contributing to the next stage in the process. An assembly line can apply to many units within Design and Technology. It is particularly suited to projects requiring multiple parts, such as the Year 6 Automata or Year 5 Bridge units in upper Key Stage 2 because it allows more pupils to work on the same product. You will need to consider what each of the steps will be and how many assembly lines you will have. For example, you could have a five-stage process with three assembly lines and pairs on each station.

The mass production method will drive your class to work together and consider products they require collectively or to fulfil the needs and wants of others. You may provide the class with ideas for this or set them a challenge to consider where a product may be helpful in the classroom or for upcoming events. For example, book sleeves for a storybook they all have access to. By switching the focus of the product to a collective goal, you are changing the mindset that the product will be for themselves or a friend or family member — something pupils are very used to in Design and Technology.

To differentiate this method, mix a range of abilities to work on stations in pairs or small groups—this way, the pupils can support and learn from each other.

Please refer to the Presentation: Mass production.

Limit the resources to a set number of groups or pairs.

Products are created in batches (groups) using an assembly line. When one batch is complete, the next batch will start — it might be similar but with some differences in colour, taste, or material. Each product within a batch is identical.

Batch production in the classroom allows you to organise the pupils into teams to create a different batch of the same product. Food products lend themselves particularly well to this method, and you or the pupils can tweak the recipes for each team to complete. Another reason for this is quite often, a recipe will make more than one serving, and it is a way of avoiding pupils creating multiple servings each.

The batch production method will encourage your class to work together in teams and consider products that are required collectively or to fulfil the needs and wants of others. You may provide the class with ideas for this or set them a challenge to consider where a series of products may be helpful in the classroom or for upcoming events—for example, batches of savoury and sweet tarts where the base recipe is the same but the additional ingredients vary with each batch.

To differentiate this method, consider how each assembly line’s product outcome could provide stretch for the more able and allow pupils to practise essential skills for those requiring more support. For example, one batch may be more complex with additional details and another larger with fewer decorative elements.

Please refer to the Presentation: Batch production.

Each pupil creates their own product.

Job production is also known as a one-off or unique production. This method focuses on bespoke products that are made one at a time for a specific user or set of criteria. Most of our Design & technology projects suggest allowing pupils to create their own products across a unit.

This approach allows children to:

Many industries rely on job production, especially those that cater to personalised events and customised sizes, such as special occasions and milestones. You could even consider landmarks such as Big Ben.

Please refer to the Presentation: Job production.

Each pupil within a class or team must have the opportunity to complete various stages of an assembly line, even if you reduce the amount of time spent on each step, for example, by halving the load of measuring, marking out and sawing wood for products with multiples of the same parts. Pupils will still need to experience new and continue to develop existing practical skills, followed by time to reflect on their progress during and after each project. Evidence pupil progress by taking photographs as they work together and on various stages of the product.

Demonstrate how materials and other resources can be recycled and reused in projects and touch upon the current sustainability problems that we face today. Encourage staff and pupils to collect and store unused materials and scraps from previous projects in a designated storage area or box. They can be beneficial when pupils decorate and finalise their designs, giving them plenty of creative options.

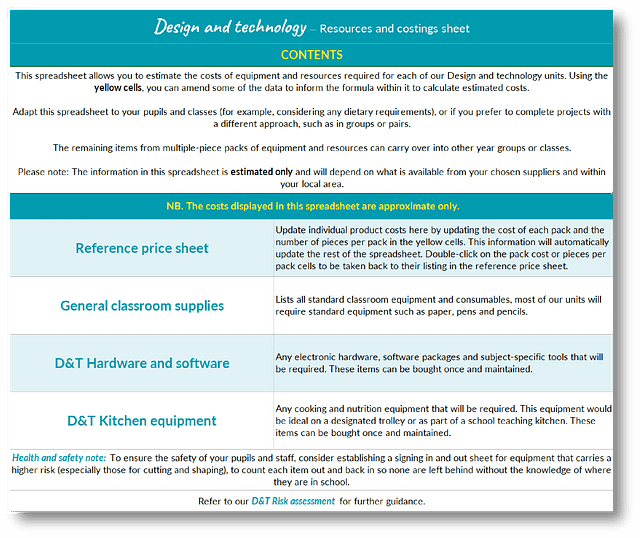

Design and technology – Resources and costings sheet

Another considerable benefit of approaching the units in an alternative way (mass or batch) is to reduce the overall unit cost.

Resources will instead account for the number of products you decide for each production method, whether along an assembly line in mass production or as part of a batch.

The Design and Technology – Resources and costings sheet allows you to estimate the costs of equipment and resources required for each Design and Technology unit. You can amend some of the data using the yellow cells to inform its formula to calculate estimated costs. Adapt this spreadsheet to your pupils and classes (for example, considering any dietary requirements), or if you prefer to deliver a unit using the mass or batch production methods outlined above.

Please note: The information in this spreadsheet is estimated only and will depend on what is available from your chosen suppliers and within your local area. The remaining items from multiple-piece packs of equipment and resources can carry over into other year groups or classes.

To ensure the safety of your pupils and staff, consider using a signing-in and out sheet for equipment that carries a higher risk, especially those for cutting and shaping. Establish class routines, health and safety rules and expectations before beginning any practical project.

Efficient resource management in Design and Technology doesn’t have to compromise learning outcomes. Instead, shifting from individual work to collaborative methods like mass, batch, or job production can enrich pupils’ skills, including teamwork, problem-solving, and resilience, while promoting sustainability. The ‘Design and Technology – Resources and costings sheet’ aids in cost estimation and resource management. Creativity and innovation can thrive despite resource constraints, preparing pupils for a dynamic, problem-solving future.